Table of Contents

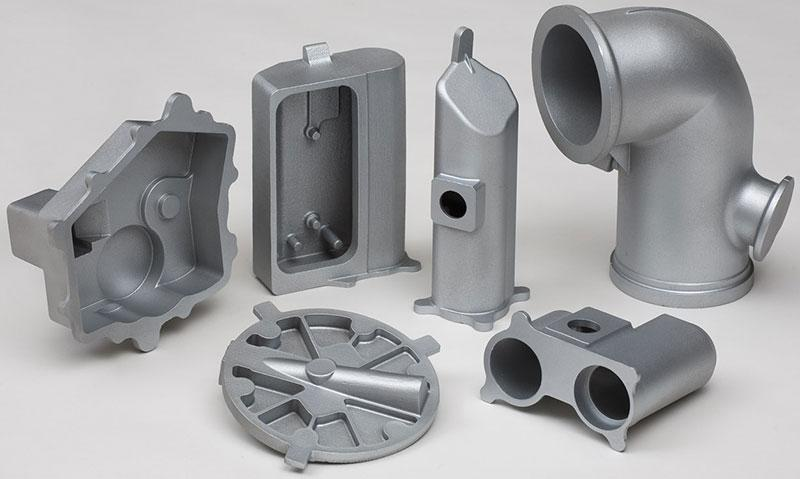

Permanent mold casting is a precision metal casting process that uses reusable molds made from steel or cast iron to produce high-quality, consistent components. Unlike sand casting, where molds are destroyed after each use, permanent molds can be used repeatedly, making the process efficient and economical for medium to large production runs.

It is commonly used for non-ferrous metals such as aluminum, magnesium, and copper alloys, offering excellent dimensional accuracy, smooth surfaces, and improved mechanical strength. This method is widely adopted in industries such as automotive, aerospace, and industrial machinery, where durability and uniformity are crucial. In this guide, we explore its process, advantages, applications, and how to find a reliable permanent mold casting company.

What is Permanent Mold Casting?

Permanent mold casting is a metal casting process that uses reusable molds made from durable materials such as steel or cast iron. Unlike sand casting, where molds are destroyed after each use, permanent mold casting allows repeated use of the same mold, making it ideal for producing medium to high volumes of parts with consistent quality. The process is primarily used for non-ferrous metals such as aluminum, magnesium, and copper alloys, which have melting points low enough not to damage the metal molds.

The key idea behind permanent mold casting is repeatability. Once the mold is created and properly maintained, it can produce thousands of identical castings. The process provides greater dimensional accuracy, improved surface finish, and enhanced mechanical properties compared to expendable mold methods. Because the mold is metallic, it cools the molten metal faster, resulting in a finer grain structure and stronger parts. This combination of precision and durability makes it an attractive option for industries where quality and uniformity are essential.

History of Permanent Mold Casting

The origins of permanent mold casting date back to the early industrial period, when foundries began experimenting with metal molds to improve productivity and consistency. Initially, casting was done using sand or clay molds, which had to be remade for every part. Although inexpensive, those molds limited precision and surface finish. As the demand for higher-quality metal components grew, manufacturers sought more durable mold materials that could withstand repeated use.

The first practical applications of permanent mold casting appeared in the late 19th century, particularly in the production of small aluminum and brass parts. During the early 20th century, advances in metallurgy made it possible to design stronger molds that could handle higher thermal stresses. The process gained prominence in the automotive and aerospace industries after World War II, when aluminum became a preferred material for lightweight components. Over time, the technique evolved from simple gravity-pour molds to sophisticated low-pressure and vacuum-assisted systems.

Types of Permanent Mold Casting

Although the general concept of permanent mold casting remains consistent, several variations have been developed to meet different manufacturing needs. Each type modifies how the molten metal enters and solidifies in the mold, influencing the properties of the final product.

Gravity Permanent Mold Casting

This is the most traditional form of the process. The molten metal is poured into the mold under the influence of gravity. It is simple, cost-effective, and well-suited for small to medium-sized castings with uniform wall thickness. Gravity permanent mold casting is commonly used for aluminum and magnesium parts, providing excellent dimensional consistency and surface finish.

Tilt Pour Permanent Mold Casting

In tilt pour casting, the mold is gradually tilted as molten metal is introduced. This controlled movement allows the metal to flow smoothly, minimizing turbulence and air entrapment. As a result, the castings tend to have fewer internal defects and improved mechanical properties. The method is especially useful for complex geometries where uniform metal flow is critical.

Low-Pressure Permanent Mold Casting

Low-pressure casting involves forcing molten metal into the mold using low gas pressure, typically from beneath the mold cavity. This technique gives better control over metal flow, reduces oxidation, and allows the molten metal to fill thin sections or intricate details more effectively. It is often used for high-integrity components in the automotive and aerospace sectors where strength and reliability are essential.

Vacuum Permanent Mold Casting

This method uses a vacuum to draw molten metal into the mold cavity. By reducing air pressure, the risk of gas porosity and oxidation is minimized. Vacuum casting is ideal for producing parts that require high structural integrity and minimal inclusions, such as aerospace components or high-performance machinery parts.

Each of these types offers unique advantages, and the choice depends on factors such as material, part complexity, production volume, and desired mechanical properties.

What are the Permanent Mold Casting Processes?

The process of permanent mold casting involves several carefully controlled stages, from preparing the mold to removing the finished part. Each step affects the quality of the final casting and must be executed with precision.

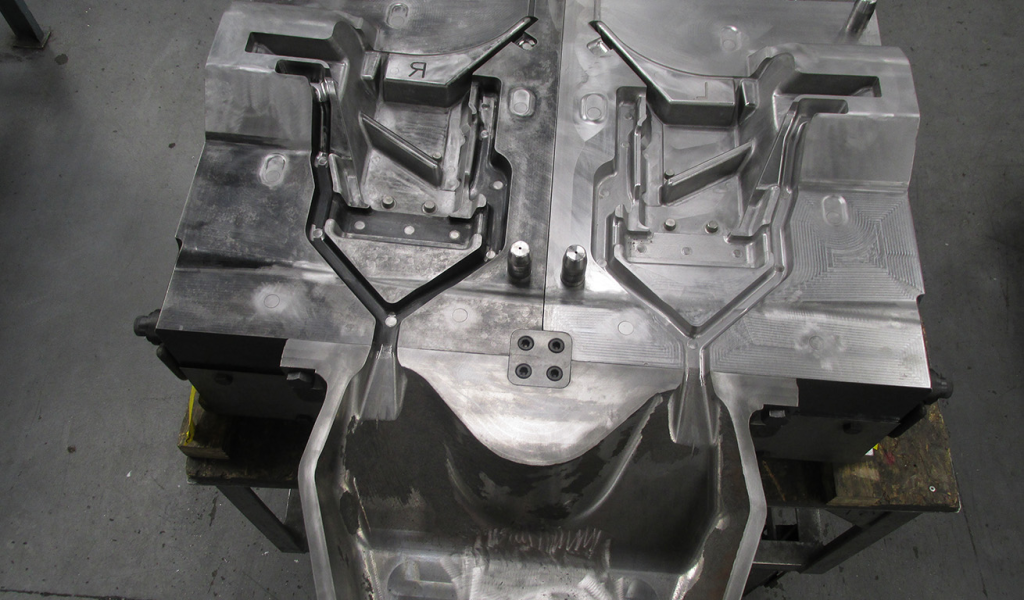

Mold Design and Preparation

The process begins with mold creation. The mold is made from strong metals such as steel or cast iron and designed in two or more sections to allow easy removal of the casting. Engineers design the mold to accommodate shrinkage, provide proper gating and venting, and ensure smooth metal flow. Before casting, the mold is preheated to a specific temperature to prevent thermal shock and coated with a refractory or graphite-based substance that prevents the metal from sticking and helps regulate cooling.

Melting and Pouring

Once the mold is ready, the chosen metal alloy is melted in a furnace. In gravity casting, the molten metal is poured directly into the mold cavity. In low-pressure or vacuum variants, the molten metal is either pushed or drawn into the mold to control flow and minimize turbulence. The pouring phase determines how well the mold fills and directly influences defect formation.

Solidification and Cooling

After pouring, the molten metal begins to solidify within the mold. Because the mold is metallic, it conducts heat away from the molten metal rapidly, creating a fine-grained structure with enhanced strength and durability. The cooling rate must be carefully controlled to avoid warping or internal stresses.

Casting Removal and Finishing

Once the metal has solidified sufficiently, the mold is opened, and the casting is ejected. Any gating or riser material is trimmed off, and the surface may be cleaned, machined, or heat-treated to achieve the desired properties. Since the mold is reusable, it is cleaned and recoated for the next casting cycle. Proper maintenance ensures the mold’s longevity and consistent part quality over many cycles.

Permanent mold casting is thus a blend of metallurgy, thermal control, and precision engineering, all aimed at producing consistent, high-quality metal components.

What are the Advantages of Permanent Mold Casting?

Permanent mold casting offers numerous advantages that make it stand out among metal casting methods, particularly for medium to high production volumes.

Superior Dimensional Accuracy

Because the molds are rigid and reusable, permanent mold casting produces parts with excellent dimensional consistency. The process maintains tight tolerances across thousands of cycles, minimizing the need for extensive machining and ensuring parts fit precisely in their assemblies.

Improved Surface Finish

The metallic surface of the mold allows smoother metal flow and a finer finish on the final part. Compared to sand casting, which often leaves a rough texture, permanent mold castings have cleaner surfaces that require less post-processing.

Enhanced Mechanical Properties

The rapid cooling rate associated with metal molds refines the grain structure of the casting, improving tensile strength, hardness, and fatigue resistance. Components produced this way often demonstrate superior performance in demanding applications.

High Production Efficiency

Once the mold is manufactured, the casting cycle is fast, allowing for higher output and lower per-unit costs. This efficiency makes permanent mold casting particularly attractive for long production runs of identical parts.

Reduced Waste and Environmental Benefits

Since the mold is reused repeatedly, material waste is minimized, and there is less reliance on disposable sand or binder materials. This not only reduces costs but also makes the process more environmentally sustainable.

Despite its benefits, permanent mold casting does have limitations. The initial cost of mold fabrication is relatively high, and it is generally best suited for non-ferrous alloys. However, for companies seeking a reliable balance between qua

Applications of Permanent Mold Casting

Permanent mold casting is used across a wide range of industries because of its ability to produce high-quality components efficiently.

Automotive Industry

One of the largest users of permanent mold casting is the automotive sector. Engine components, transmission housings, brake system parts, and suspension elements are frequently made using this process. The high strength and precision of these parts ensure durability and safety while maintaining a lighter overall vehicle weight.

Aerospace and Defense

In aerospace manufacturing, permanent mold casting is valued for producing lightweight yet strong aluminum and magnesium components. Aircraft parts, turbine housings, and structural brackets benefit from the superior mechanical properties and consistency the process provides.

Industrial Equipment

Permanent mold casting is also used for industrial machinery, pumps, and valve housings. These components often require high corrosion resistance, precise tolerances, and smooth surfaces for proper sealing and functionality.

Consumer and Electrical Products

From kitchen appliances to lighting fixtures and motor housings, many consumer goods rely on permanent mold casting for its efficiency and clean finish. The process is also used to make electrical enclosures and components that demand both strength and accuracy.

Its versatility allows permanent mold casting to meet the requirements of industries that depend on repeatability, reliability, and cost-effectiveness.

How to Test the Quality of Permanent Mold Casting

Ensuring the quality of castings is crucial for performance and safety. Several aspects of quality testing help determine whether a casting meets required standards.

Dimensional and Visual Inspection

Every finished part is measured against its design specifications to confirm dimensional accuracy. Visual inspections identify surface imperfections such as porosity, cracks, or misruns that may affect performance.

Mechanical Property Testing

Tensile strength, hardness, and impact resistance are measured to verify that the casting meets its intended mechanical standards. Because permanent mold casting can enhance structural properties, these tests confirm that the process parameters are properly controlled.

Non-Destructive Testing

Techniques such as X-ray inspection, ultrasonic testing, and dye penetrant testing are commonly used to detect internal voids, inclusions, or cracks without damaging the part. These tests ensure internal integrity, especially for safety-critical applications.

Metallurgical Analysis

Examining the microstructure of the metal reveals grain size, uniformity, and any inclusions or impurities. Consistent grain patterns indicate proper cooling and solidification, while deviations can reveal process issues.

Mold Condition Monitoring

The quality of the castings depends heavily on the condition of the mold itself. Regular inspection for wear, erosion, and coating integrity ensures that each casting cycle maintains the same level of precision and finish. Proper maintenance extends the mold’s lifespan and safeguards part quality.

Through consistent testing and control, manufacturers can ensure that permanent mold castings deliver the expected strength, appearance, and performance.

Where to Find a Good Permanent Mold Casting Company

Finding a reliable permanent mold casting company requires more than just comparing prices. The ideal partner should combine technical expertise, advanced equipment, and a commitment to consistent quality.

A good casting company should have in-depth experience in mold design, metal alloy selection, and process optimization. It should also maintain strong quality control systems, including dimensional inspection, non-destructive testing, and metallurgical analysis. Efficient communication and the ability to provide design support are also vital, as they help customers refine their parts for manufacturability and cost efficiency.

If you are looking for a trusted and experienced manufacturer, Fuchun Casting is a reliable choice. The company specializes in various casting processes, including permanent mold casting, and serves a global clientele with precision-engineered metal components. Fuchun Casting focuses on providing durable molds, consistent product quality, and professional support throughout every stage of production. Their experience in aluminum and other non-ferrous castings makes them a dependable partner for projects requiring both performance and efficiency.

When selecting a company, it is wise to evaluate their track record, production capabilities, and quality assurance systems. A competent partner not only produces castings but also helps you optimize designs, reduce costs, and ensure your parts perform as intended.

Summary

Permanent mold casting is a proven and efficient metal casting process that combines the durability of reusable molds with the precision needed for high-quality parts. Its advantages include improved surface finish, tight dimensional control, enhanced mechanical strength, and excellent repeatability. Although the initial tooling cost is higher than that of expendable methods, the long-term benefits in quality and production efficiency make it ideal for medium and large production runs.

The process’s versatility has made it a cornerstone in industries such as automotive, aerospace, and industrial equipment manufacturing. By understanding the different types of permanent mold casting, the steps involved, and how to ensure quality, engineers and buyers can make informed decisions when choosing this process for their products.

To achieve the best results, partnering with a skilled and experienced manufacturer like Fuchun Casting ensures your components are made with precision, consistency, and technical excellence. Whether for large-scale production or specialized parts, permanent mold casting remains one of the most reliable and effective manufacturing methods in modern industry.